Resin Driveways

Resin Driveways ~ Resin Pathways ~ Resin Patio Areas ~

Resin Pool Surrounds ~ Resin Spa Surrounds ~ Resin Non-Slip Interior Floors ~ Resin Courtyards

Resin surfacing and resin-bound driveways can be an excellent solution for many property owners, especially if you prioritise aesthetics, durability, and eco-friendliness. However, the best solution depends on your specific needs. It's essential to weigh the pros and cons, compare it to other options, and make an informed decision that aligns with your vision for your specific property goals. This page should address the most common questions and offer peace of mind when it comes to making a decision. Plus we offer a 10-year guarantee!

A Durable Resin Installation

Is Closer Than You Think...

Resin-Bound Surfacing Enquiry

WORKING TOGETHER

We work with you to come up with the very best solutions for your resin surfacing projects.

The first stage of your project is an important one and Greenway knows from experience that many customers have suffered the negative effects of using contractors that don't carefully ensure every phase of a resin surface installation is executed properly.

Rest assured that once you book a site visit with Greenway, our experts will check to make sure you have crossed your 't's and dotted your 'i's in all the right places.

Going straight to the installation stage without making sure the previous steps are taken care of can often have a knock-on effect with the rest of the resin installation, which could potentially cost you much more money.

Where do I start if I want a resin bound surface installation?

A resin bound surface uses a solution that results from mixing resin and aggregates together in a forced action mixer. This creates a blend that can be trowelled onto a surface to provide a smooth, flat finish. A resin bound system is also known in the trade as 'stone carpet'.

Greenway ensures the following important steps are taken with every resin surfacing project:

01

Preparation

Preparation work to any original surface is key to a long lasting beautiful resin bound surface.

02

Choose Materials

Decide on a colour from our colour samples. Also choose if you want a standard or UV protection coating.

03

Book in the Start Date

Arrange the best project starting date with a Greenway site manager. Allow at least a day or two for installation.

04

Clear Access Points

Ensure all access points and driveways are clear of cars, and equipment. Aggregate sacks may be stacked on the roadside along with a forced action mixer, so make sure frontages are clear.

Resin Driveway Installations

Greenway installs resin-bound driveways across Dorset, Wiltshire, Hampshire, Surrey, Berkshire, Oxfordshire and London and has had many satisfied customers for over ten years.

All the Greenway resin driveways are UV resistant using permeable resin.

Each resin driveway installation retains its looks for years, as Greenway only uses the finest materials and equipment.

With a wide range of coloured aggregate choices, your driveway will complement your home with many textures and finishes to reflect your preference and personality.

Greenway is fully insured with a 10-year resin driveway installation guarantee.

There are many options for hard-surfacing driveways asphalt, concrete, block paving and brick. However, the resin-bound surfacing system is impressive as no other system can structurally and aesthetically offer the same strength and resistance.

The Key Benefits of a Resin Driveway Installation

- UV resistant

- Colour-stable

- Long lifespan

- Permeable and SuDS compliant

- Slip-resistant

- Frost-resistant

- Weed-resistant

- Easy to maintain

- Easy to clean

- Seamless

- Limitless design options

- Smooth, flat and durable surface

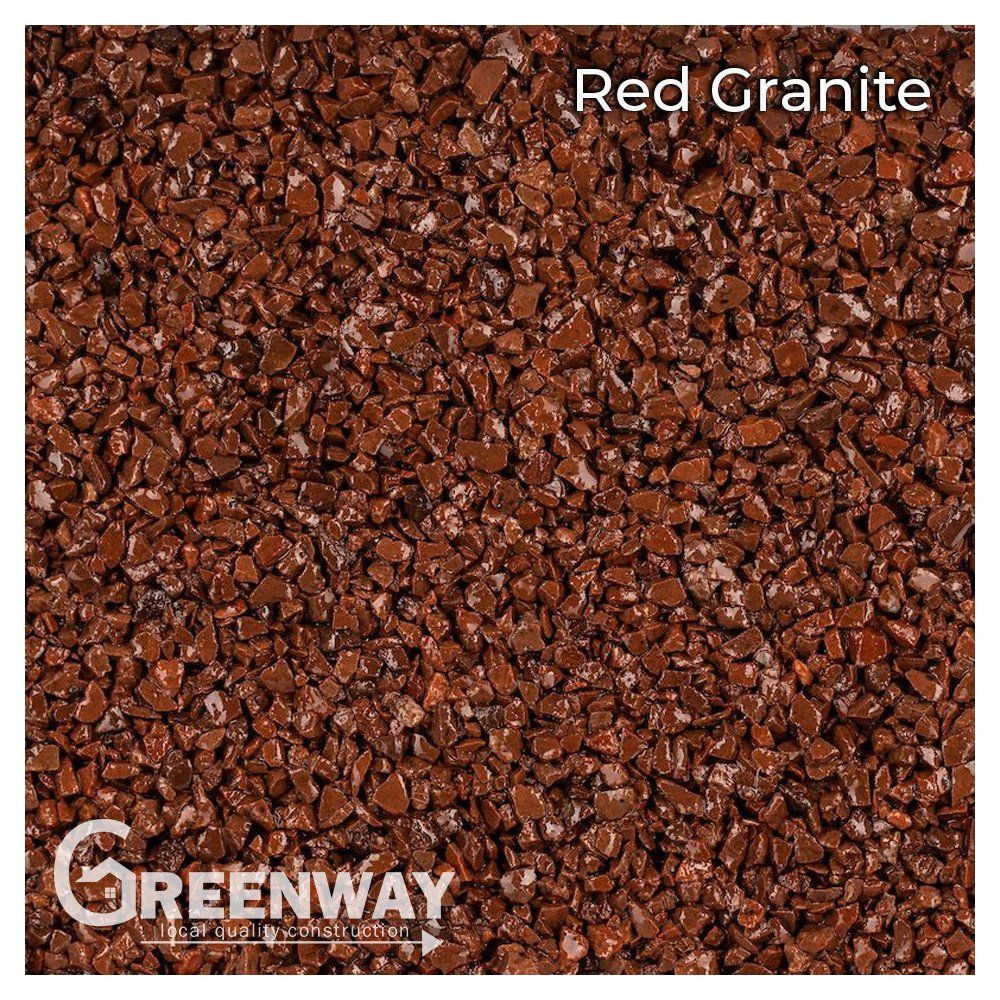

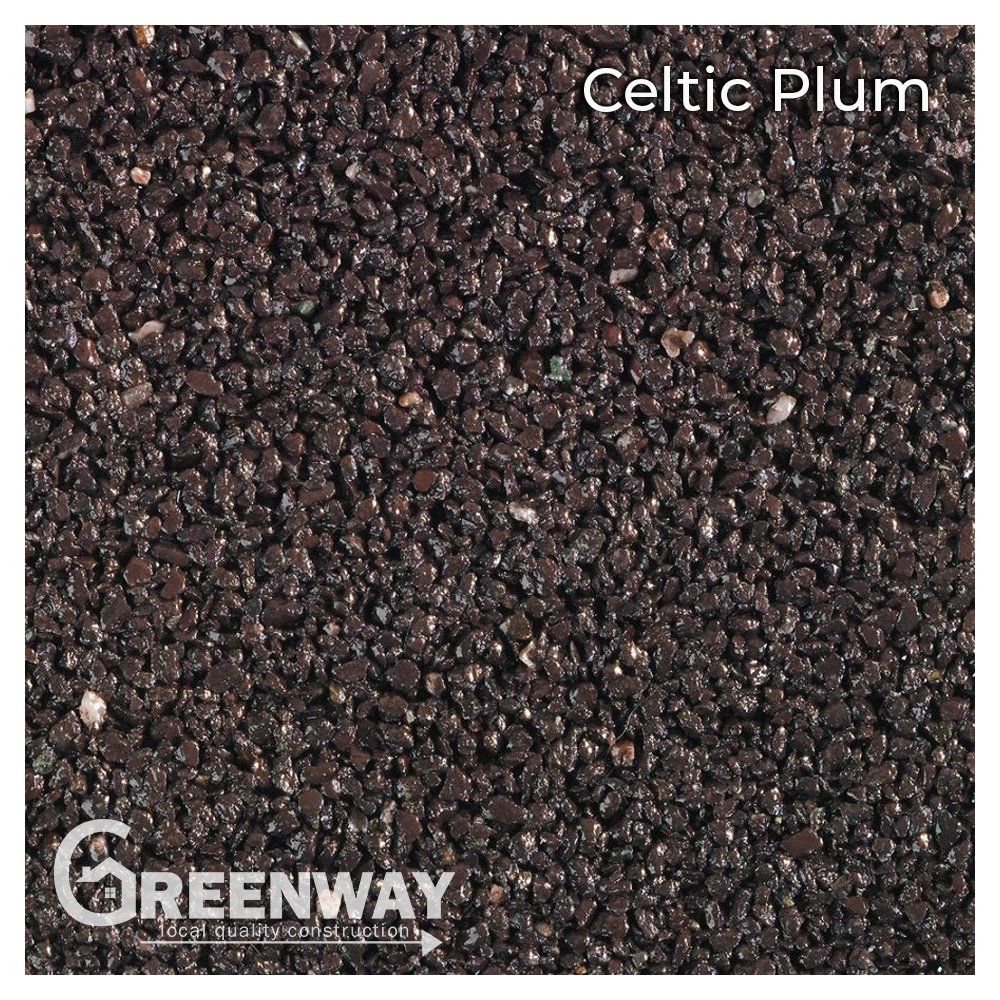

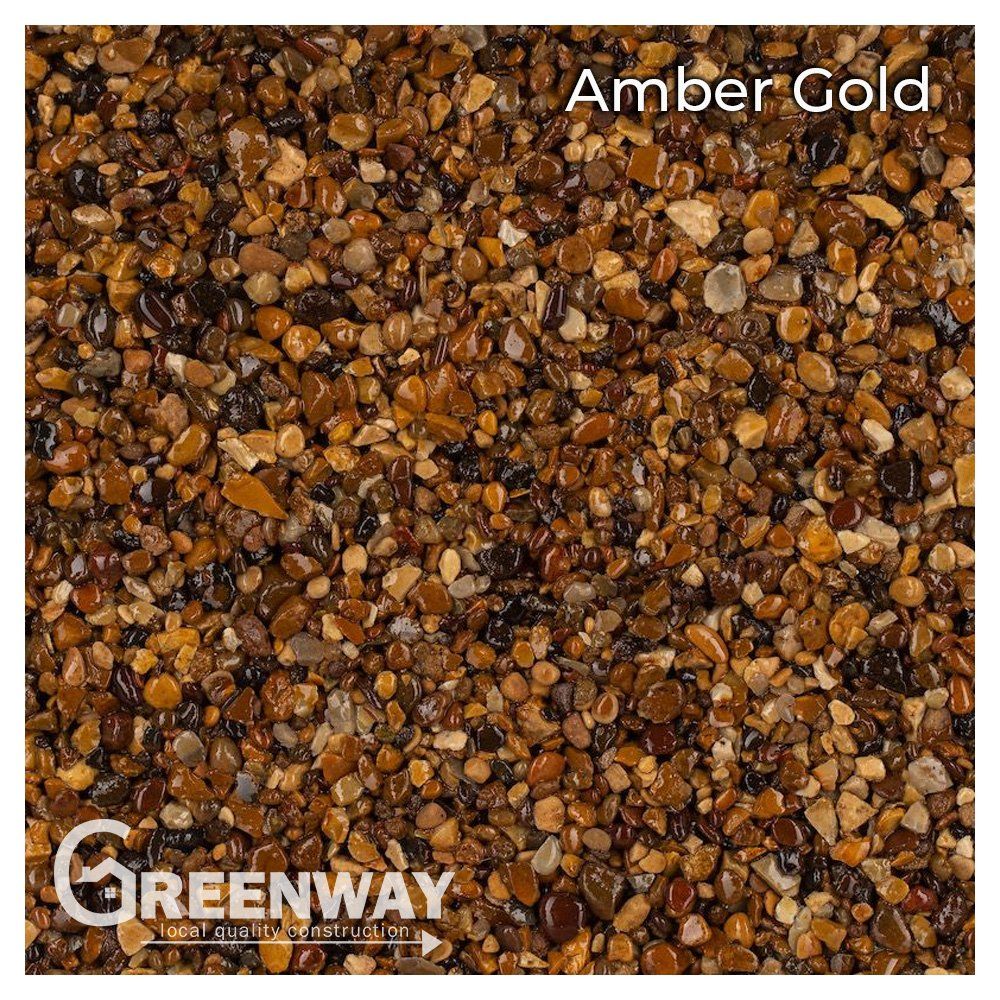

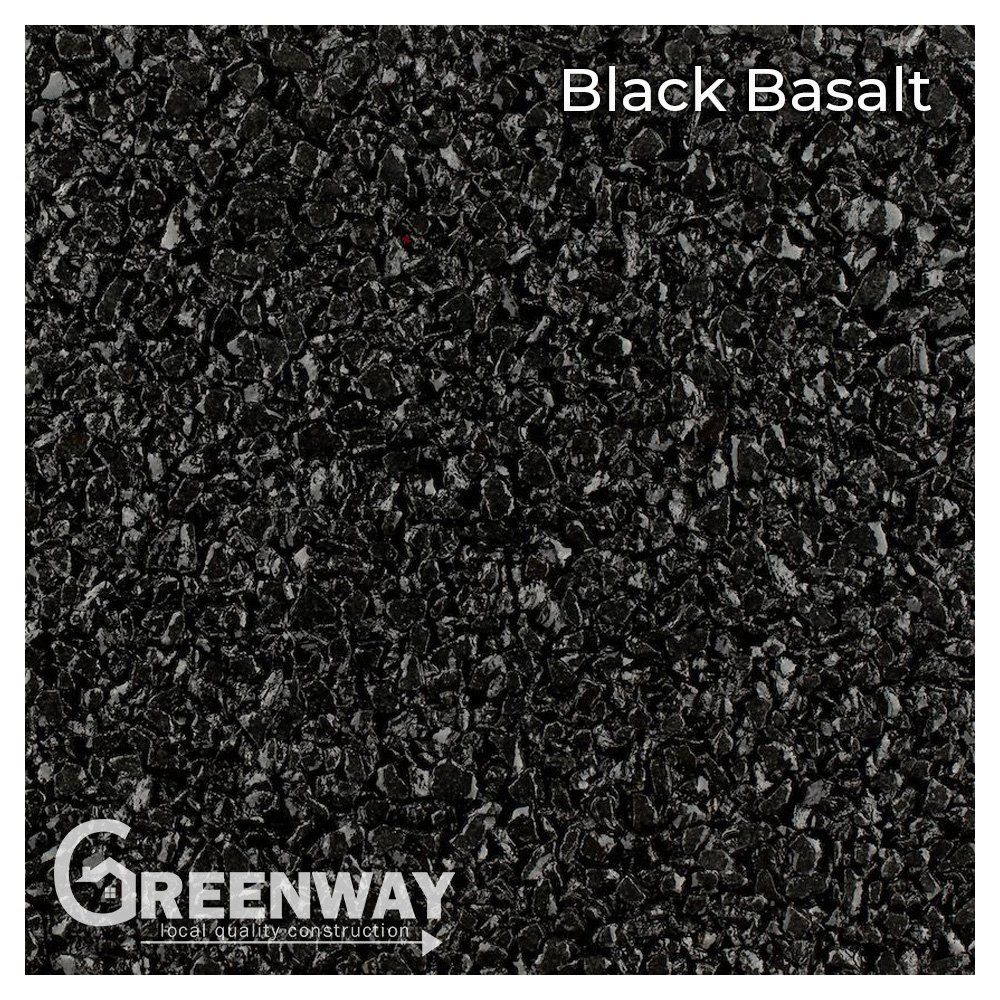

Resin Bound Aggregate Samples

The selection of colours and finishes available for resin bound gravels and aggregates are vast and sometimes overwhelming.

Greenway gives every customer their full choice of aggregate finish and each is graded and processed specifically for resin bound surfacing projects including driveways, paths and patios.

The extensive range of colourful aggregates Greenway offers is the most widely used in the industry due to its quality and consistency.

View the most popular choices of resin bound aggregates below.

Photo Gallery

Resin Bound Installations

Take a look at some of our recent resin bound surfacing projects below:

Disadvantages of resin surfacing...

- Cost: One of the primary disadvantages of resin-bound driveways is the upfront cost. They tend to be more expensive than some traditional driveway materials like gravel or tarmac. The cost can be a significant factor for homeowners on a tight budget.

- Installation Complexity: Resin-bound driveways require professional installation. The process involves mixing resin with aggregates and then applying it to the surface. If not done correctly, it can result in a subpar finish, so finding a skilled installer is crucial.

- Curing Time: Resin-bound surfaces can take some time to fully cure and harden. During this period, they may not be suitable for heavy use, which can be an inconvenience during installation.

- Slippery When Wet: While resin-bound surfaces are generally slip-resistant, they can become slippery when very wet. This can be a safety concern. (However, extra traction areas can be made with fine glass grit after installation while the resin is curing.)

- Cracking and Damage: While resin-bound driveways are durable, they are not completely immune to damage. Heavy objects or sharp impacts can cause cracks or chips in the surface. Repairing such damage may require professional assistance.

- Weed Growth: Although resin-bound driveways are relatively weed-resistant, it's not uncommon for weeds to occasionally grow through cracks or joints. Regular maintenance may be needed to keep the surface weed-free.

- Limited DIY Options: Unlike some other driveway materials that homeowners can install themselves, resin-bound driveways are not a DIY-friendly option. This limits cost savings for those who prefer DIY projects.

Advantages of resin surfacing...

- Resin-bound surfacing is a hard-wearing surface option that offers the dual advantage of being durable yet pleasing to look at with a clean, stony appearance.

- Resin surfacing reduces ponding and promotes easy run-off. It also benefits trees planted on the surface, allowing water to reach the roots without laying loose gravel.

- Due to its high porosity, resin surfacing receives minimal damage and degradation caused by freeze/thaw cycles. So crucial for UK weather!

- Greenway offers a choice of UV stable resin surfacing, protecting it from sun damage and breakdown.

- The aggregate stone has fantastic decorative potential, as they are available in various shapes, sizes and colours.

- Resin surfacing can be laid with no joins, allowing the surface to contour to any awkward shapes or prominent features.

- The rough aggregate texture also offers high slip resistance, so installations are popular with families of children and the elderly.

Frequently Asked Questions

Here are some answers to commonly asked questions about resin driveway installations?